Selective laser

melting (SLM) technology is a layer-by-layer additive manufacturing technology

using a laser (heating a fine metal powder with various types of laser

radiation intensity distributions and consolidation). Today, the SLM method is

the most rapidly developing and widely studied [1-4] additive manufacturing

technology. During the industrial implementation of this technology, we faced

the problem of visual control, analysis and data visualization. A large number

of scientific works are devoted to various aspects of the development of

technological solutions using methods and algorithms of machine vision

(Computer Vision), for example, [5-14]. Moreover, problems are often

considered, the solution of which allows the use of explicit linear algorithms.

Examples of such problems are: finding barcode or QR code, determining the

position of the product, adjusting the processing path, analyzing the number

and quality of holes in the perforation of the material, determining the

geometry of the working sheet, quality control of the weld, determining the

geometry of flat products or products made by selective laser melting SLM.

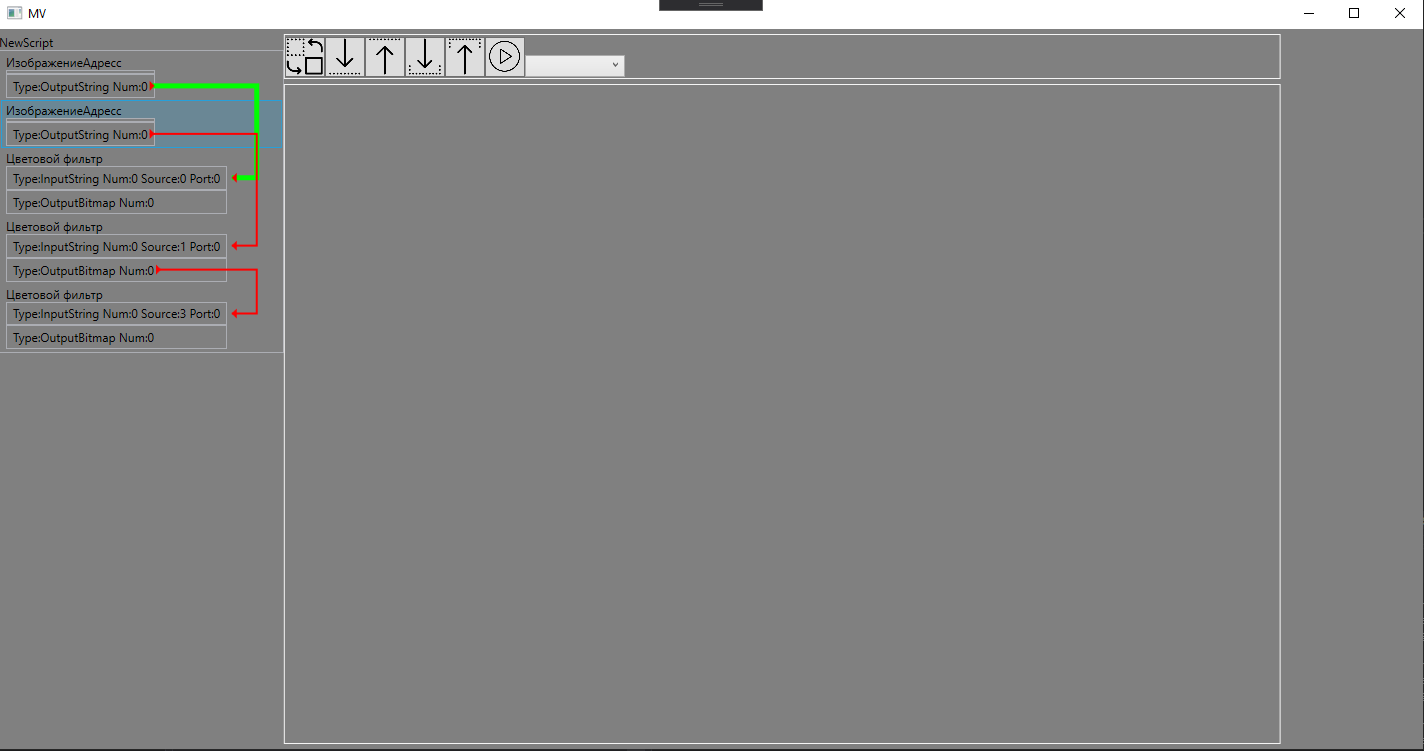

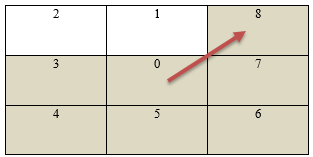

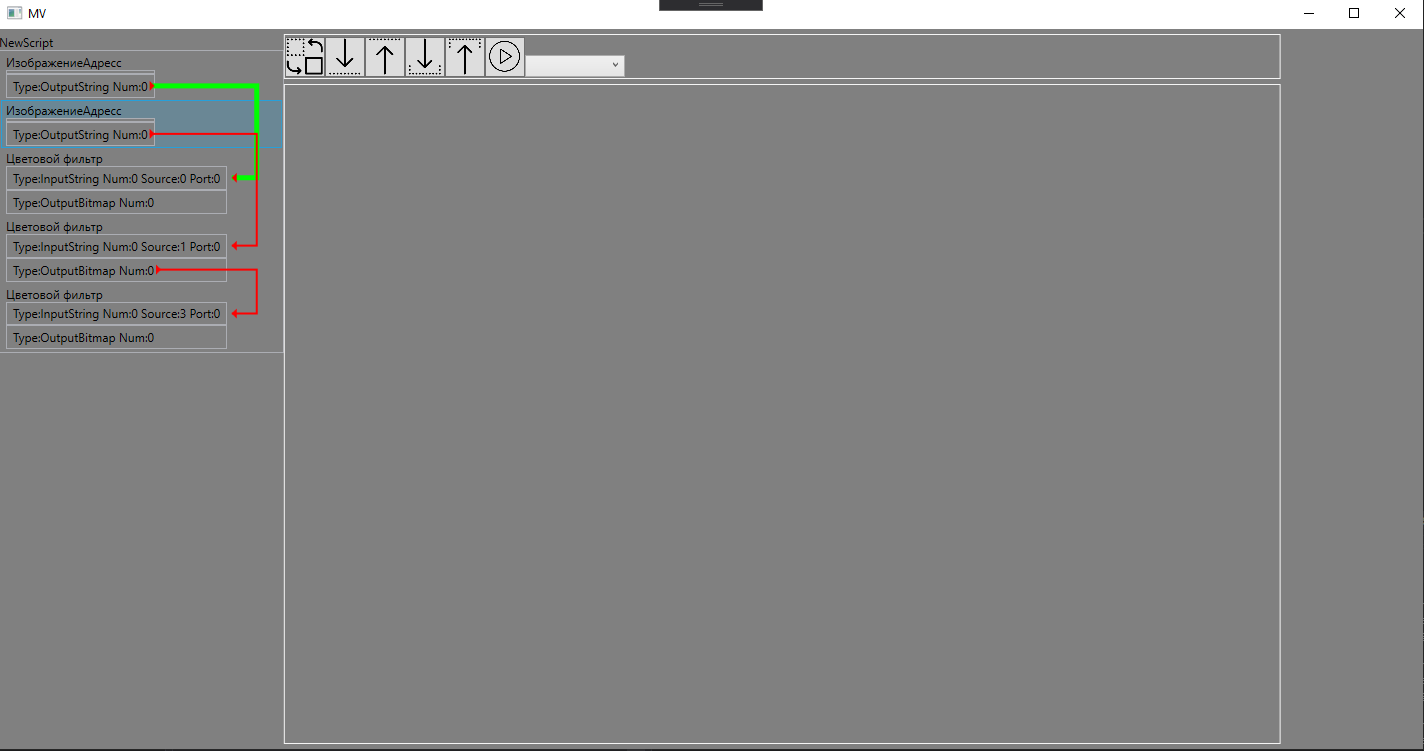

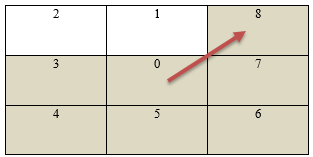

Mentioned tasks are solved in a built software environment

with an emphasis on accessibility and ease of use. The user can collect data

from various image sources, define a processing sequence using various image

processing filters (Fig. 1), and perform analysis using prepared software tools.

For this purpose, the LAMachineVision software platform was made (Fig. 1).

Fig. 1.

Sequence

of image processing.

The software platform uses a visual programming

approach that has proven itself by providing a wide range of users with the

ability to solve machine vision problems. The same principle applies to such

development environments and platforms as LabVIEW [11] and Cognex VisionPro.

LAMachineVision is written in the C# language of the .NET Framework version

4.7.2. WPF is used to create the main user interface, using DirectX graphics

technology and using the declarative XAML language. The user interfaces of the tools

used (various filters and processors) are implemented using WPF and Windows

Forms tools using the GDI/GDI+ graphics technology. Due to the use of the C#

language, the main operating system for the LAMachineVision platform is Windows

version 7 and higher. The main part of the platform is written according to the

Model-View-ViewModel (MVVM) pattern.

Using the link establishment function, a connected

directed graph is formed, along which the system will subsequently transfer

data from sources to filters and further along the route specified by the user.

The only condition for this construction is the work with absence of cycles in

the solution graph.

The use of a high level of abstraction allows us to exclude

a wide range of restrictions for developers, allowing to implement own filters

and processors and simply embed them into the platform using the API, allowing

third-party users, including technologists and researchers who do not have

programming skills, to solve a wide range of machine vision tasks. API

(Application Programming Interface) - an application programming interface, a

description of the ways (a set of classes, procedures, functions, structures or

constants) in which one software can interact with another software. In order

for a new filter to be embedded in a decision tree, it is enough that its outer

software shell implements a simple IProcessing interface with a small number of

supported properties and methods:

•

string Name { get; set;

}

•

int Num { get; set; }

•

ObservableCollection < IInputStep >

InputSteps { get; set; }

•

ObservableCollection < IOutputStep >

OutputSteps { get; set; }

•

ObservableCollection < Info >

InfoInputSteps { get; set; }

•

ObservableCollection < Info >

InfoOutputSteps { get; set; }

•

void DoProcess();

•

void UpdateInfo();

•

Page UiPage { get; set;

}

The transfer of information is carried out using I / O

"ports", also with a high level of abstraction, there are no

additional requirements for both the user interface and the specific

implementation. Thus, each filter and processor is an object that implements

the IProcessing interface, receives data for its work from input ports,

performs some action and passes the result of its work further along the

decision graph through the output port.

This approach allows both using your own

implementations of machine vision algorithms and using third-party libraries

and frameworks, in particular, AForge.NET and OpenCV solutions were used. To

connect various data sources, interaction with Basler machine vision cameras

using the Pylon SDK packages, with Hikvision cameras using the Hikvision SDK

packages, and IP cameras using the DirectShow framework is implemented.

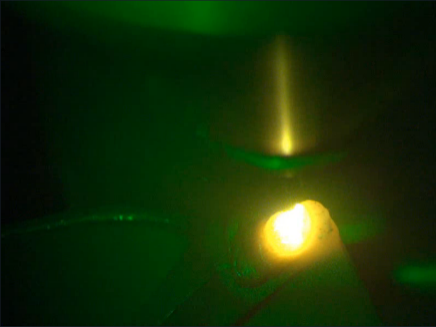

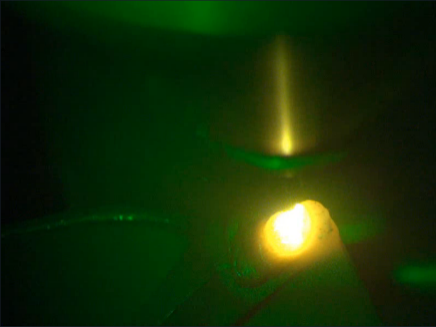

One

of the possibilities implemented by the platform is the interaction with

various camera models. In particular, the use of Basler matrix cameras (Fig. 2)

was tested, which are mainly used in factory automation, traffic monitoring,

retail, as well as medicine and life sciences.

Fig. 2.

Matrix

camera.

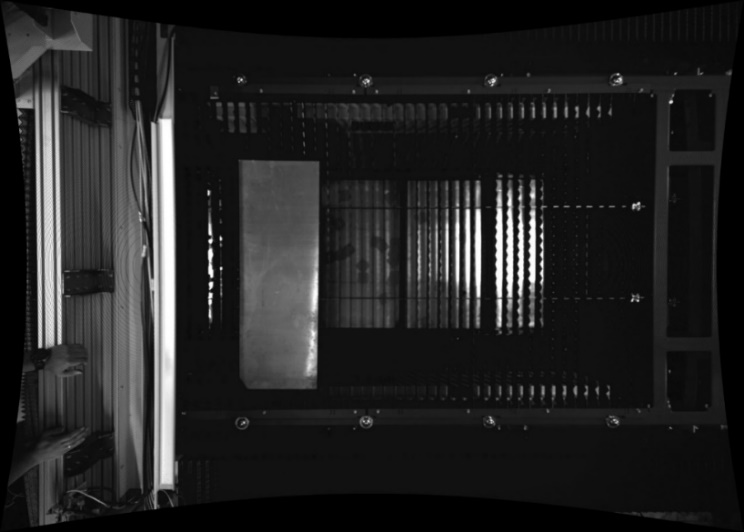

Further,

the data from the camera are used for subsequent analysis or video recording

(Fig. 3) of the processes under study. The use of machine vision cameras allows

you to monitor processes in environments inaccessible to the observer. In

particular, in DMD technology (direct metal deposition, technology for

manufacturing metal parts by direct metal deposition).

Fig. 3. Video

recording of the DMD process of welding a turbine blade.

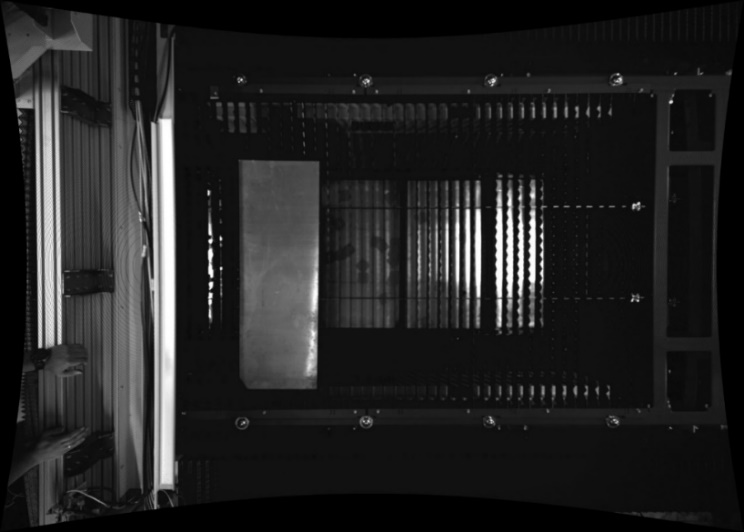

One of the most

common machine vision tasks is object recognition. One of the special cases of

such a task in industry is finding a sheet in the working field of the machine.

One of the options for solving a similar problem using the capabilities of the platform

under consideration has been implemented. A Basler matrix camera is used as the

data source. Sheets can be located in different parts of the working field,

have different shapes and consist of different materials, so it is supposed to

formulate the task as a search for abstract objects in the image. For this,

various image comparison filters are used. The idea of the

approach is simple: get an image of an empty workspace, then get a new image of

the space with the sheet already in place and recognise its location by

comparing it with the original image. In addition, the implemented algorithm

for correcting radial distortion caused by the use of wide view lenses is

demonstrated (Fig. 4).

Fig. 4. Correction

of distortion.

Several filter

options have been implemented that determine the difference between two images,

allowing you to compare a field with a sheet and a field without a sheet and

find the desired object in the image. For color images, there are several

similar processors, which are based on different metrics for calculating the

color distance between pixels, and several methods for finding corners in an

image using different implementations of corner detection algorithms.

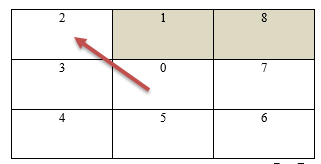

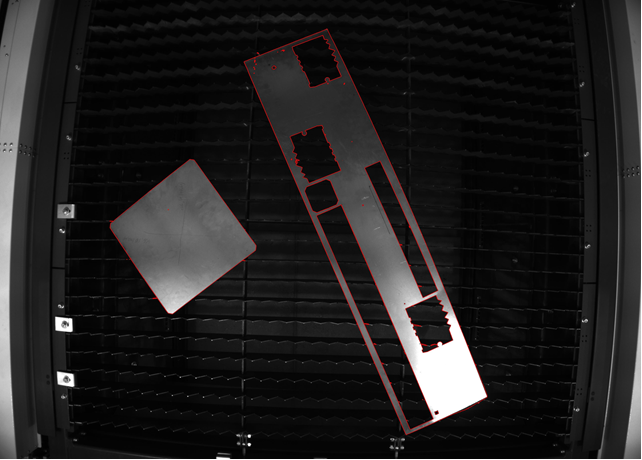

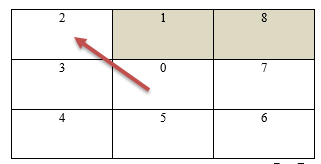

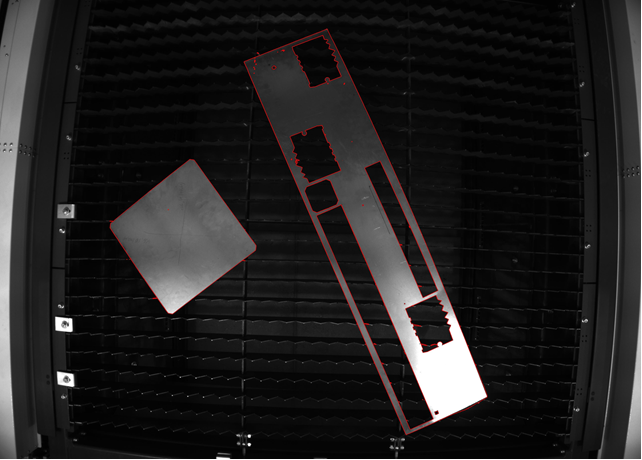

An algorithm for

determining the contours of an object from previously found angles has been

developed and implemented (Fig. 5, 6).

Fig. 5. Searching

for boundaries algorithm (inner boundary).

Fig. 6. Searching

for boundaries algorithm (outer boundary).

The idea of the

algorithm is simple: based on the filters mentioned earlier, the image is

binarized (most often based on comparison with the background image) and the

set of corners is determined, the upper left unused corner is taken from the

set of defined ones. If the top pixel is black, then the bypass is

counterclockwise; if it is white, then the bypass is clockwise.

Thus,

we divide the contours into

outer

and

inner.

Fig. 7.

Found

sheets.

The quality of the

result obtained depends on the quality of the image, lighting and the accuracy

of the selection of processing parameters. The same approach is applied to find

the geometry of the fused layer in the SLM process. The preview image is a

photo of the previous layer. The new image is a photo of the next fused layer.

The problem of finding and analyzing the quality of holes during perforation is

solved in a similar way.

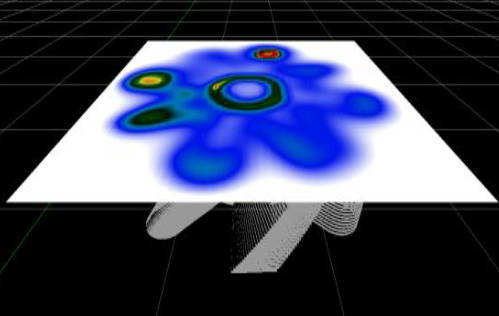

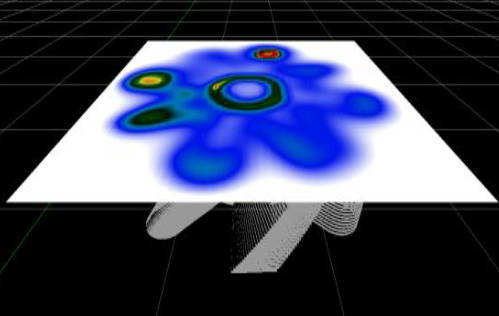

Data on the fused

layer of powder material are processed in a similar way in the manufacture of

products by the method of selective laser melting. After determining the

geometry of each layer, it is compared with the pre-calculated one and the

so-called “layer map” is formed (Fig. 8), on which the data of the temperature

model are subsequently superimposed.

Fig. 8. Composition

of temperature data on the product layer (one of the representation models).

Tracking systems are widely used in laser technology

for processing products from various materials. When using pulsed laser

radiation of the picosecond and femtosecond range in the process of

micromachining, there is often an increased sensitivity of the parameters of

the technological process of processing to the deviation of the focal length of

the laser-optical system from the surface of the product.

In laser micromachining processes, micron deviations

are critical, therefore, accurate and fast methods of compensating for the

error in real-time movement of the product surface relative to the optical

system during processing are required. The algorithms and methods of machine

vision included in the developed software automation platform make it possible

to provide the required parameters of the micromachining process.

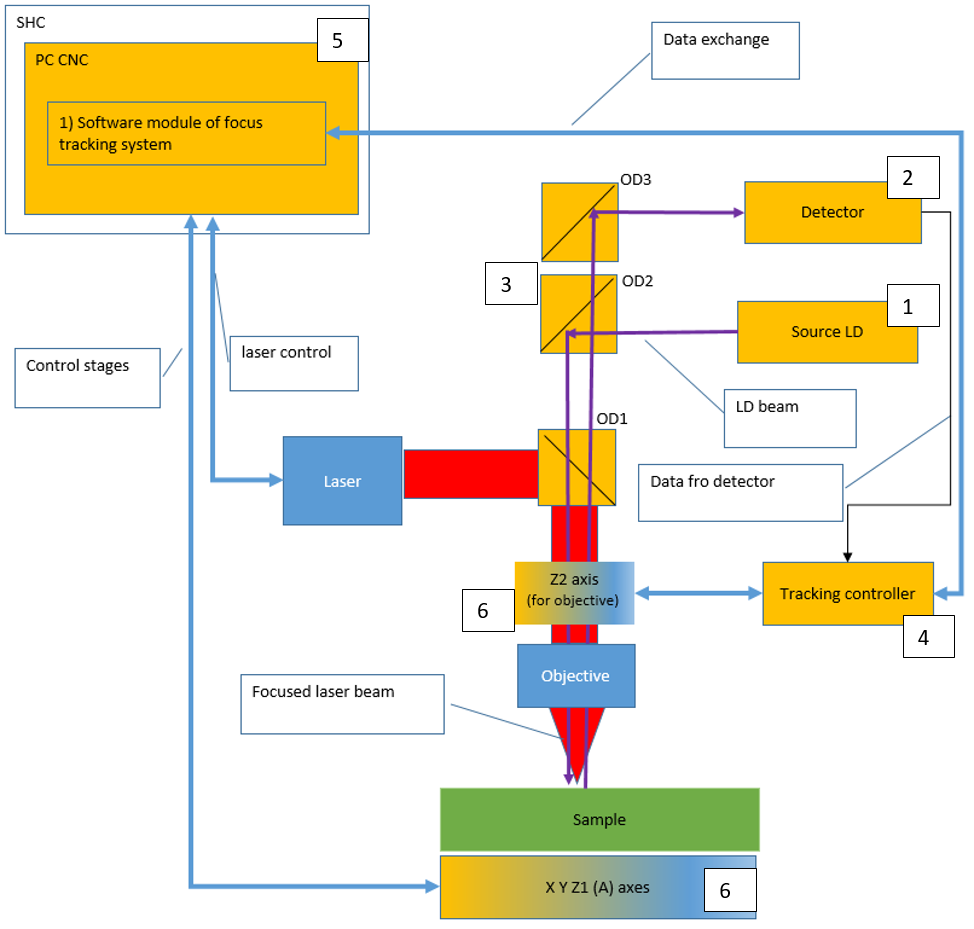

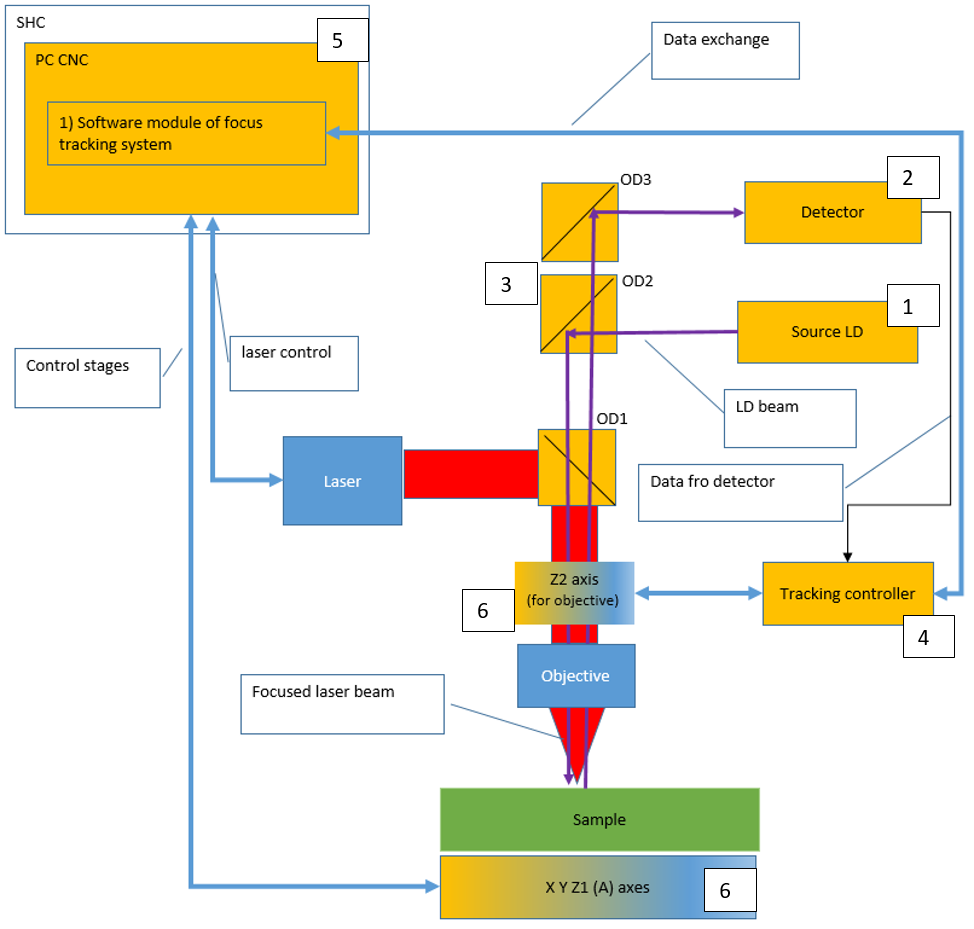

For the processing of dielectrics and metals, a system

for automatically controlling the position of the laser beam focus (Fig. 9) is

proposed, using the idea of a laser optical rangefinder

(triangulator), which has the following advantages:

1. non-contact measurement, which is safe for the

workpiece,

2. the ability to work with dielectrics,

3. no mechanical moving joints,

4. the possibility of using the system in especially

clean rooms,

5. high performance, i.e. high measurement and

processing speed, and high accuracy,

6. the possibility to obtain a wide range of

characteristics by changing the source, detector and geometry.

In general terms, the automatic control system for the

position of the focus of the laser beam of special technological equipment

using a laser optical rangefinder can be classified: 1. According to the basic

characteristics. 2. According to the location of the laser rangefinder relative

to the optical system of the working laser. 3. If possible, synchronous

operation of measurement systems, calculation of the automatic control system

for the position of the laser beam focus and the control system for the kinematic

systems of the machine tool with numerical control. 4. According to the design

of the rangefinder. 5. According to the type of adjustment on the Z axis. 6.

According to the capabilities of the built-in analysis of the measured data. A

number of devices have the ability to pre-filter data, ensuring the stability

and repeatability of the results.

Fig. 9. Common block scheme of the automatic control system

for the position of the laser beam focus.

According to the location

of the laser rangefinder relatively to the optical system of the working laser,

the system of automatic control of the position of the laser beam focus (Fig.

9) proposed is coaxial, which ensures the operability of the tracking system

for any laser processing trajectories in the XY plane. According to the type of

adjustment along the Z axis, two possible versions are possible - with the

movement of the sample itself (Z1), and in the version with the movement of the

objective (Z2). Focus adjustment by moving the lens is recommended because the

lens is lighter than a product with a holding and alignment tools. This allows

for more dynamic focus adjustment. The system is synchronous, i.e. focus

adjustment is performed during laser processing. By type of execution, the

system is distributed, i.e. it’s ready for integration into an opto-mechanical

laser processing system.

The automatic control

system for the position of the laser beam focus includes:

1. "Source (LD)"

- a laser diode (Laser diode LD), the source of laser radiation of the tracking

system. The LD emission wavelength for most dielectrics is in the range of

650~900nm. This makes it possible to use optical coatings of optical components

between the first and second harmonics of the operating range of laser

radiation, as well as the possibility of integrating a coaxial video system

with illumination. There is a possibility of amplitude modulation of radiation

by external control.

2. "Detector" -

a matrix or line camera with a digital interface.

3. "OD1",

"OD2", "OD3" - optical dividers, optical elements, the

dielectric coatings of which are selected depending on the radiation wavelength

of the "Source (LD)" and the working laser for micromachining

"Laser". The presence of "OD3" is due to the possibility of

using a coaxial video channel for automation and application of machine vision

algorithms.

4. "Tracking

controller" - the main controller of the automatic focus position control

system, which reads and processes data from the detector in real time,

mathematical processing of the received data and calculation of the focus

position, control of the Z coordinate, by sending commands to the CNC system of

the laser machine. This controller works autonomously, a communication line of

this controller with the CNC system is also provided for transferring

parameters and monitoring states. The controller of the automatic focus

position control system is implemented on the basis of a field-programmable

gate array FPGA.

5. "SHC" - a

software and hardware complex of a laser system, including a software module

for automatic tracking of the sample profile in the CNC system of the laser

installation, as well as a user interface for controlling, configuring and

testing the automatic focus position control system. The software and hardware

complex can work autonomously without the participation of the CNC.

6. Z axis (Z1/Z2) - can be

implemented on any type of drive that provides the required accuracy and dynamics:

linear drives, piezo actuator, etc. The Z axis is controlled by the interaction

of the controller with the appropriate driver.

The collimated laser beam

of the automatic focus position control system from the LD source passes

through the power lens to the surface of the product, part of this radiation is

reflected from the surface, passes back through the power lens, and the

reflected beam is recorded on a linear detector. The position of the peak on

the linear sensor of the detector corresponds to the current distance between

the lens and the surface of the workpiece. One of the peak positions is stored

in the tracking controller as the focus position. While tracking the sample

surface, the tracking controller moves the lens in such a direction that the

position of the current peak tends to the position of the stored focus. The

variable length of the return pass to the camera ensures the adjustment of the

scale of the automatic focus position control system, namely the accuracy and

measurement range at a fixed camera size. Setting the source beam collimation

allows you to adjust the size of the laser spot on the surface of the product.

Thus, the possible types

of configurations of surface tracking systems are analyzed, the configuration

is selected, its composition, structure and principle of operation are

described.

Because of the work carried out, it became possible to:

1. Solve a number of tasks of machine vision and

scientific visualization in the framework of the industrial implementation of

new laser technologies, in particular, the technology of selective laser melting.

2. Create a specialized machine vision software

platform that makes it possible to simplify the solution of a wide range of

machine vision and scientific visualization tasks.

3. Provide the possibility of video recording of

processes in isolated environments, determination of the boundaries of objects

in the image, analysis and processing of visual data, formation and

presentation of a picture of heat distribution in a three-dimensional object,

we implemented process based on the data obtained as a result of a numerical

experiment in accordance with the mathematical model of the object.

4. Realize the combination of calculated data on the

geometry of the product, data obtained by analyzing video data from visual

observation tools, with data on the thermal distribution of the parameters of

the selective laser melting process.

5. Create a system for automatic control of the

position of the laser beam focus, designed to be built into laser

micromachining systems and laser systems for additive technologies and which

can significantly improve the quality, repeatability and productivity of laser

micromachining processes using pulsed laser radiation of picosecond and

femtosecond range.

The created machine vision software platform has been

tested and implemented in software and technological solutions used in high-tech

equipment.

The authors are

grateful to the management of the group of companies "Lasers and Apparatus

TM" for assistance in the material and technical support of experimental

studies and modeling of the process under consideration.

[1]

Оптико-электронный комплекс для исследования процессов

тепло- и массообмена лазерным бесконтактным методом / А.В.

Ведяшкина [и др.] // Научная

визуализация. 2019 № 11.3.

C.

43-53

[2]

Aluminum alloys for selective laser

melting – towards improved performance / P. Rometsch, Q. Jia, K. Yang, X. Wu //

Additive Manufacturing for the Aerospace Industry, 2019, P. 301-325

[3]

Mechanical properties of Ti6Al4V and

AlSi12Mg lattice structures manufactured by Selective Laser Melting (SLM) / M.

Mazur [et al.] // Laser Additive Manufacturing: Materials, Design,

Technologies, and Applications. 2016. P. 119-161

[4]

Heat Source Modeling in Selective

Laser Melting / E. Mirkoohi, D. Seivers, H. Garmestani, S. Liang // Materials.

2019, № 12, 2052.

[5]

Система технического зрения для информационного

обеспечения автоматической посадки и движения по ВПП летательных аппаратов/

С.М. Соколов, А.А. Богуславский, Н.Г. Фёдоров, П.В. Виноградов // Известия ЮФУ.

Технические

науки.

2015. № 1.

С. 96-109.

[6]

Machine vision based automated

inspection approach for clutch friction disc (CFD) / S. Kaushik, A. Jain, T.

Chaudhary, N.R. Chauhan // Materials Today: Proceedings.

2022. № 62.1.

P. 151-157

[7]

Степанов Д.Н. Методы и алгоритмы определения положения

и ориентации беспилотного летательного аппарата с применением бортовых

видеокамер // Программные продукты и системы. 2014. № 1. С. 150-157.

[8]

Краснобаев А. А. Обзор алгоритмов детектирования

простых элементов изображения и анализ возможности их аппаратной реализации

[Электронный ресурс] // Институт прикладной математики им. М. В. Келдыша

Российской академии наук. 2005. URL:

http://www.keldysh.ru/papers/2005/prep114/prep2005_114.html

(дата обращения 17.08.2022)

[9]

Методы автоматического обнаружения и сопровождения

объектов. Обработка изображений и управление / Б. А. Алпатов, П. В. Бабаян, О.

Е Балашов, А. И. Степашкин // М.: Радиотехника, 2008.

C. 176.

[10]

Рахматулин И.

Нейросети, глубокое обучение, машинное зрение в сельском хозяйстве. Краткий

обзор для 2021 года. [Электронный ресурс] // Препринт. 2021.

URL:

https://www.researchgate.net/publication/350280155_Nejroseti_glubokoe_obucenie_ masinnoe_zrenie_v_selskom_hozajstve_Kratkij_obzor_dla_2021_goda

(дата

обращения 17.08.2022)

[11]

Иванов П.В.,

Бойков А.В. Преимущества применения программного комплекса

LabView

для создания систем машинного зрения

// Записки Горного института. 2011. № 192.

C. 216-218.

[12]

Болотова Ю.А.,

Друки А.А., Спицын В.Г. Методы и алгоритмы интеллектуальной обработки цифровых

изображений: учебное пособие // Т.: Томский политехнический университет, 2016.

— 208 c.

[13]

Smith

S.M., Brady J.M. SUSAN—A New Approach to Low Level Image Processing //

International Journal of Computer Vision. 1997.

№

23, 45–78 (1997)

[14]

Rosten

E., Drummond T. Machine Learning for High-Speed Corner Detection. // In:

Leonardis, A., Bischof, H., Pinz, A. (eds) Computer Vision – ECCV 2006. ECCV

2006. Lecture

Notes

in

Computer

Science, № 3951. p. 430–443.

[15]

Молотков А.А.,

Третьякова О.Н. О возможных подходах к визуализации процесса селективного

лазерного сплавления // Научная визуализация. 2019. Т11. № 4. С. 1-12.

[16]

И. Ф. Лебёдкин,

А. А. Молотков, О. Н. Третьякова Математическое моделирование сложного

теплообмена при разработке лазерных

SLM

технологий [Электронный ресурс] // Труды МАИ. 2018.

№ 101.URL:

https://trudymai.ru/upload/iblock/118/Lebyedkin_Molotkov_Tretyakova_rus.pdf?lang=ru&issue=101

[17]

Молотков А.А.,

Третьякова О.Н. Визуализация результатов моделирования процесса селективного

лазерного сплавления //

GraphiCon

2019 (Брянск, 23–26 сент. 2019 г.): сб. трудов междунар. конференции /

Брянский государственный технический университет. Брянск. 2019. С. 78-81.

[18]

Кондратенко В.С.,

Сапрыкин Д.Л., Третьякова О. Н., Тужилин Д. Н.

Разработка системы автоматического управления

подстройкой фокуса для технологии лазерной микрообработки материалов. /

Приборы.

2022.№ 4. С.26-31.

[19]

Tretiyakova

O.N., Molotkov A.A.

About the development of applied software for mechatronic

systems of SLM technology / MATEC Web of Conferences.

Volume

362, 2022. XXII

International Conference on Computational Mechanics and Modern Applied Software

Systems (CMMASS 2021).

Article Number 01031. Number of page(s) 8. DOI

https://doi.org/10.1051/matecconf/202236201031

. Published online 14

September 2022.

[20]

Молотков А.А.,

Третьякова О.Н. Визуализация и анализ визуальных данных в аддитивной технологии

производства оптико-электронных приборов/ Материалы МНТК «Графикон2022» 19-22

сентября 2022. Рязань.